Understanding the Role of Slitting Machines in the Supply Chain

In the intricate tapestry of modern manufacturing, slitting machines emerge as pivotal components within the supply chain. These specialized machines are designed primarily for cutting large rolls of materials into narrower strips, enhancing efficiency and precision in production processes. At Hengli, we recognize the critical importance of slitting machines in optimizing workflows, reducing waste, and ultimately delivering high-quality products to the market.

What Are Slitting Machines?

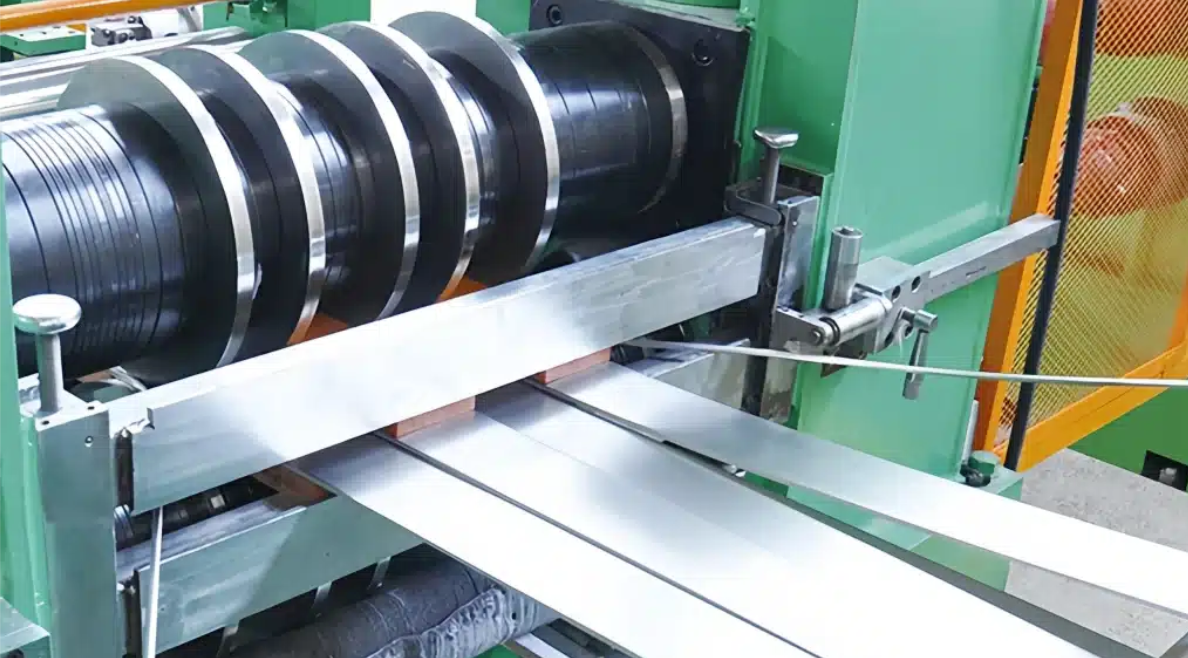

Slitting machines are advanced equipment used to slice materials such as paper, plastic, metal, and textiles. They operate by feeding a roll of material through a series of blades that cut the roll into desired widths. The precision of these machines ensures that each strip is uniform, which is essential for further processing and application.

Types of Slitting Machines

Rotary Slitting Machines: Utilizing rotating blades, these machines provide high-speed slitting capabilities, making them ideal for materials that require quick processing. They are commonly used in industries such as packaging and textiles.

Shear Slitting Machines: These machines employ a straight blade that slices through the material, offering a clean cut. They are particularly effective for thicker materials like metal and are widely used in manufacturing sectors.

Score Slitting Machines: Score slitting involves making a shallow cut on the surface of the material, allowing it to be folded or separated easily later. This method is frequently used in paper and film applications.

Importance of Slitting Machines in the Supply Chain

Enhancing Efficiency

At Hengli, we understand that efficiency is the cornerstone of a successful supply chain. Slitting machines significantly enhance production efficiency by:

- Reducing Material Waste: By producing precise cuts, slitting machines minimize excess material, leading to cost savings and environmental benefits.

- Streamlining Production Processes: Automating the slitting process allows manufacturers to increase output while maintaining quality standards, thereby shortening lead times.

Quality Assurance

Quality control is paramount in any manufacturing process. Slitting machines contribute to maintaining high standards through:

- Consistent Dimensions: The advanced technology behind slitting machines ensures that every strip produced meets specified dimensions, reducing the likelihood of defects.

- Versatile Application: Different materials can be processed without compromising quality, making slitting machines indispensable in diverse industries.

Flexibility and Customization

Modern slitting machines offer unparalleled flexibility, allowing manufacturers to easily switch between different materials and specifications. This adaptability is crucial in responding to changing market demands. At Hengli, our slitting machines are designed with user-friendly interfaces, enabling quick adjustments and customizations.

Integration of Slitting Machines in the Supply Chain Process

From Raw Material to Finished Product

The integration of slitting machines into the supply chain can be visualized through the following stages:

Raw Material Acquisition: High-quality raw materials are sourced, ensuring that the slitting process begins with the best inputs.

Slitting Process: The raw materials are fed into slitting machines, which cut them into specific widths according to production requirements.

Quality Control: Post-slitting, the strips undergo rigorous quality checks to ensure they meet industry standards.

Packaging and Distribution: Once quality assurance is complete, the finished products are packaged and prepared for distribution, ready to meet customer demands.

Case Study: Slitting Machines in Action

Consider a manufacturing facility that produces packaging materials. By implementing Hengli slitting machines, the facility observed:

- A 30% reduction in material waste due to precise cutting.

- An increase in production speed by 50%, allowing for quicker turnaround times.

- Enhanced product quality, leading to fewer returns and higher customer satisfaction rates.

Choosing the Right Slitting Machine for Your Needs

When selecting a slitting machine, several factors should be considered to ensure it meets your production requirements:

Material Type

Different materials require different slitting techniques. It is essential to choose a machine designed for the specific type of material you will be processing.

Production Volume

Assess your production volume needs. For high-volume operations, investing in advanced slitting machines with higher speed and efficiency is crucial.

Budget Considerations

While high-quality slitting machines may require a larger initial investment, the long-term savings in material waste and increased productivity can justify the cost.

Support and Maintenance

Consider the availability of support and maintenance services. A reliable manufacturer like Hengli offers comprehensive support to ensure your machines operate at peak performance.

Conclusion

In the ever-evolving landscape of manufacturing, slitting machines play a vital role in enhancing efficiency, ensuring quality, and promoting sustainability within the supply chain. As a professional slitting machine manufacturer, Hengli is committed to providing advanced slitting equipment to meet the diverse needs of customers. By integrating advanced technology and focusing on quality, we help companies optimize operations and meet the challenges brought by increasingly fierce market competition. Embrace the future of manufacturing with Hengli and experience the transformative impact that cutting-edge slitting machines can bring to your supply chain. Welcome to contact us to learn more about metal slitting equipment.

Slitting line machine not only for the steel serivice cutting industry, but also for the pipe industry.