Rotary Vibration Shear Line That Revolutionizes Precision Cutting

Rotary vibrating shear lines are a cutting-edge technology making waves in various industries and have become a game-changer in precision cutting and forming processes. In this article, we will delve into the complexity of this innovative system and explore its capabilities, applications, benefits and its impact on different industries.

Understanding Rotational Vibration Shear Lines

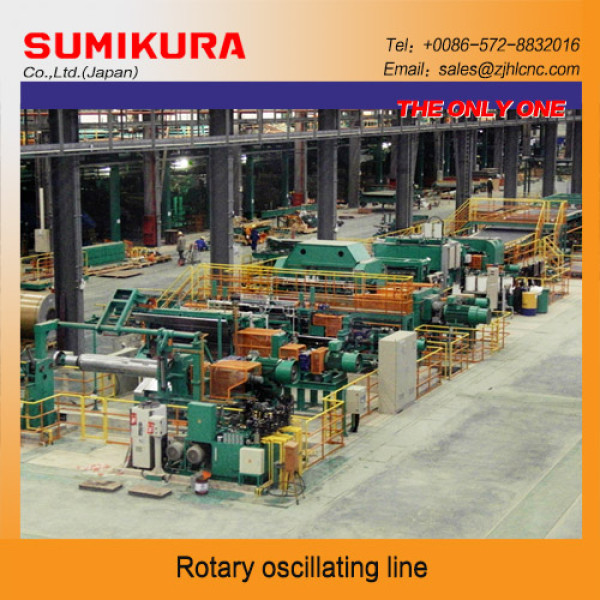

Rotary vibration shear lines, also known as rotary vibration shear lines, represent cutting-edge technology at the forefront of precision cutting and forming processes across industries. This innovative system uses specialized machinery that utilizes rotational oscillations to achieve unparalleled material-cutting accuracy. The importance of this technology lies in its ability to increase operational efficiency, deliver precise cuts and shapes, and provide manufacturers with cost-effective solutions. By revolutionizing traditional shearing methods, rotary vibrating shear lines have played an important role in industries such as automotive, textiles, and metal processing.

Advantages of Rotary Vibrating Shear Lines

Improved Precision and Accuracy: Rotary vibrating shear lines provide significant advancements in precision cutting and forming processes. The technology's ability to combine with rotational oscillation ensures unprecedented precision. This kind of precision is critical in an industry that pays attention to detail and precise measurements. Whether in automotive manufacturing, textile cutting, or metal forming, the higher precision provided by rotary vibrating shear lines results in superior quality and consistency.

Improved Operational Efficiency: One of the main advantages of rotary vibratory shear lines is the ability to significantly increase operational efficiency. The technology involves machinery designed to be seamlessly integrated into the manufacturing process, resulting in streamlined and optimized production. With faster cutting speeds and reduced downtime, companies using rotary vibrating shear lines experience significant improvements in overall efficiency. This efficiency gains not only speed up production but also help meet demanding market requirements and deadlines.

Cost-Effectiveness and Resource Optimization: Rotary vibration shear lines optimize resources in a variety of ways, helping to improve cost-effectiveness. The precision provided by this technology minimizes material waste as it ensures precise cuts and shapes, reducing the need for rework or corrections. In addition, increased operational efficiency means energy savings and reduced labor costs. While the initial investment may be significant, the cost savings in the long term make a rotary vibratory shear line a financially prudent choice for companies aiming to enhance their manufacturing processes while effectively managing operating expenses.

Industries Benefiting from Rotary Vibrating Shear Lines

Automotive Industry: The automotive industry is a major beneficiary of rotational vibration shear lines due to the complexity of manufacturing components. In automotive production, precision is crucial for components such as body panels, frames and interior elements. Rotary vibrating shear lines provide cutting-edge solutions that help improve the overall quality and efficiency of the manufacturing process by ensuring precise and consistent cuts. The technology is capable of processing a wide range of materials, from metals to composites, making it capable of meeting the diverse needs of the automotive industry.

Textile Manufacturing: Rotary vibrating shear lines revolutionize the textile industry by solving the challenges associated with the precision cutting of fabrics. In textile manufacturing, precision is crucial for creating patterns and designs, and this technology ensures clean, precise cuts with less material waste. The ability of rotary vibrating shearing lines to process different types of fabrics of different thicknesses and textures makes rotary vibrating shearing lines an indispensable tool for textile manufacturers in their pursuit of efficiency and high-quality end products.

Metal Processing and Manufacturing: Industries involved in metal processing and manufacturing benefit greatly from rotary vibrating shear lines. These industries often deal with complex metal shapes and structures, and the precision provided by this technology is critical to achieving the desired results. Whether cutting sheet metal, formed parts, or intricate details, rotary vibrating shear lines deliver the precision and efficiency required for metalworking processes. This improves product quality and reduces material waste, making metal manufacturing more cost-effective overall.

Electronics Manufacturing: In the electronics industry where miniaturization and precision are key, rotational vibration shear wires play a vital role in the manufacturing of electronic components. These shear lines facilitate the precise cutting and shaping of materials used in electronic devices, ensuring components fit seamlessly into compact designs. The technology can handle delicate materials without compromising accuracy, making it ideal for electronics manufacturers looking to achieve high precision in their production processes. From circuit boards to complex electronic enclosures, rotational vibration shear wires help improve the efficiency and quality of electronics manufacturing.

Precautions for Implementing Rotary Vibration Shear Lines

Operator Training and Safety Protocols: Implementing a rotary vibratory shear line requires a strong emphasis on operator training and the establishment of comprehensive safety protocols. Operators operating machinery must receive comprehensive training to understand the intricacies of the technology, including its operating mechanisms, maintenance requirements, and troubleshooting procedures. Safety protocols should be in place to minimize the risk of accidents and ensure the health of those working on the shear line. This includes guidance on proper use, emergency procedures, and use of personal protective equipment. By prioritizing operator training and safety, companies can mitigate the potential risks associated with implementing rotary vibration shear lines, thereby creating a safe and efficient work environment.

Regular Maintenance and Calibration Checks: Another important preventive measure for successful implementation is to have a routine maintenance schedule and regular calibration checks for your rotational vibration shear line. Regular maintenance ensures machinery is operating at peak performance, minimizing the risk of failure and extending the life of the equipment. Calibration checks are critical to guarantee the precision and accuracy of cut lines, especially in industries where minute measurements are critical. By adhering to a proactive maintenance and calibration regimen, companies can prevent unplanned outages, maintain technical efficiency, and ensure consistent, high-quality output. This preventive approach not only protects the investment in a rotary vibratory shear line but also contributes to continued operational excellence.

In Conclusion

In conclusion, the rotary vibrating shear line has proven to be a revolutionary technology that has reshaped precision cutting in various industries. Its efficiency, precision, and cost-effectiveness make it a valuable asset for companies looking for advanced manufacturing solutions. If you want to buy a rotary vibration shearing line, please contact us.

In the dynamic landscape of manufacturing technology, Hengli stands out as a reliable rotary vibrating shear line manufacturer. With a commitment to innovation, precision, and customer satisfaction, Hengli has earned a reputation as a preferred supplier to industries looking for cutting-edge solutions in precision cutting and forming processes.

In the field of rotary vibratory shear lines, Hengli has become a trusted ally in industries that pursue precision, innovation and operational excellence. With cutting-edge technology, custom solutions, and a commitment to safety and support, Hengli sets the standard for reliability in manufacturing. Choose Hengli as your precision partner and experience the difference an innovative rotary vibrating shear line can make in your manufacturing process.