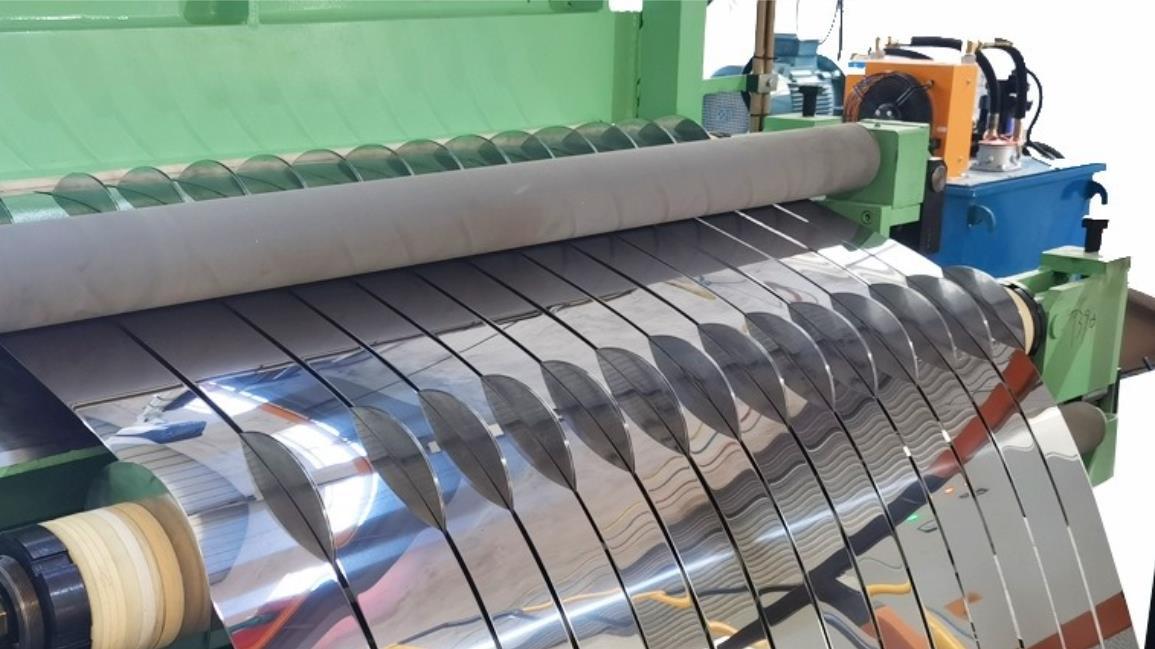

What Are the Types of Metal Slitter Belts?

The industrial belt is the product of the development of the industrial industry. After the development of the industrial belt, it has also driven the development of the industrial industry, because now the production and processing are basically produced by mechanization, and the efficiency of the mechanized production has been correspondingly improved compared with the traditional industry. As an industrial belt, combined with the machine, it has driven the development of the entire industry. The same is true of metal slitter belts. Speaking of slitter belts, what are the types of slitter belts?

Dry slitter belts:

The PU glue on the surface is very wear-resistant and resistant to cutting, which can protect the surface of the belt from being scratched and prolong the service life of the belt. The high elastic fiber in the middle can ensure that the belt provides a balanced pressure to the steel plate, and the relative movement between the belt and the steel plate is minimized. The bottom high-strength polyester braided layer has high tensile strength and good toughness, which can meet the needs of high-speed operation; and can withstand high temperature and wear. Belt dimensional accuracy is high.

Leather slitter belt:

The surface leather has high abrasion resistance, and the fine leather surface can prevent the slightest scratches on the surface of the steel plate. The high elastic fiber in the middle can ensure that the belt provides a balanced pressure to the steel plate, and the relative movement between the belt and the steel plate is minimized. The bottom high-strength polyester braided layer has high tensile strength and good toughness, which can meet the needs of high-speed operation; and can withstand high temperature and wear. Belt dimensional accuracy is high.

Oily slitter belt:

The PU rubber on the surface has a pattern, which has good friction, is very wear-resistant, and is resistant to cutting, which can protect the surface of the belt from being scratched and prolong its service life of the belt. The middle surface has holes that allow oil to penetrate. The high elastic fiber in the middle has good oil absorption and can make the belt provide a balanced pressure to the steel plate, and minimize the relative movement between the belt and the steel plate.

The bottom high-strength polyester braided layer has high tensile strength and good toughness, which can meet the needs of high-speed operation; and can withstand high temperature and wear. Belt dimensional accuracy is high. Commonly used for oily steel plate slitting.

Steel plate automatic slitting machine tension felt pad:

The steel plate is slitted and rolled up after slitting. If the surface requirements of the steel plate are not high, the method of holding the steel plate with felt pads is often used, which is economical and affordable.

The above briefly introduces several types of metal slitting machine belts. If you want to customize a metal slitting machine, please contact us.

Hengli is a professional custom sheet metal cutting equipment manufacturer in China. Hengli specializes in the R&D and manufacturing of high-end industrial automation equipment. The main products are synchronized with the world's advanced technologies and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgy processing, electric power, and metal packaging. The company aims to become a technology pioneer and market leader in the metal blanket forming industry, insist on innovation, build a brand, and prosper China's equipment manufacturing.