Why Leading Manufacturers Choose Advanced Silicon Steel Shearing Lines | Hengli's Industry-Leading Solutions

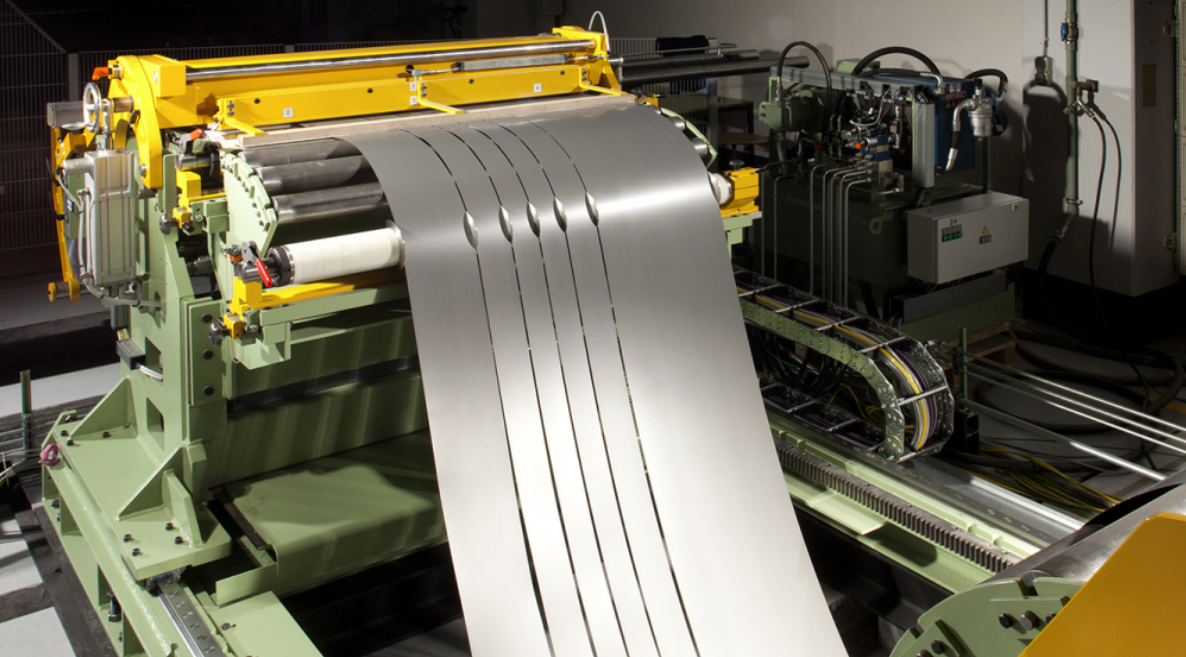

In the highly competitive landscape of steel manufacturing, precision, efficiency, and reliability are critical factors that determine industry leaders' success. As the demand for high-quality silicon steel continues to surge—driven by the needs of electric vehicles, renewable energy, and electrical appliances—the choice of shearing lines becomes more crucial than ever. Leading manufacturers worldwide are increasingly turning to Hengli’s advanced silicon steel shearing lines, recognizing their unparalleled integration of cutting-edge technology, robust construction, and optimized performance.

This comprehensive guide explores the key reasons why industry giants prefer Hengli's silicon steel shearing solutions, detailing technological innovations, operational benefits, and long-term advantages that set Hengli apart from competitors.

Unmatched Precision and Quality in Silicon Steel Shearing Line

Precision is the cornerstone of high-quality silicon steel processing. Hengli's shearing lines are engineered with state-of-the-art CNC control systems that guarantee exact cuts with minimal deformation. The automatic alignment and calibration features ensure consistent shear accuracy, reducing material wastage and enhancing product uniformity.

Our advanced shearing technology incorporates high-speed blade movement and adaptive cutting mechanisms, capable of handling thin gauge and thick-silicon steel sheets with equal finesse. This level of precision is critical for lamination stacks in transformers, motors, and inductors, where dimensional accuracy directly affects electrical performance.

Superior Efficiency and Output for High-Volume Production

In a competitive market, manufacturers demand high throughput without compromising quality. Hengli’s silicon steel shearing lines are designed to operate at maximum speeds, leveraging high-performance motors and optimized hydraulic systems. This results in faster cycle times, reduced downtime, and enhanced productivity.

The automatic sheet feeding and integrated scrap collection systems streamline the entire process, enabling continuous operation for large-scale production facilities. The modular design allows for easy upgrades and maintenance, minimizing operational interruptions and ensuring consistent output.

Advanced Technological Features for Enhanced Performance

Hengli's shearing lines are equipped with cutting-edge features that elevate performance standards:

Intelligent Control Systems: Utilize AI-driven algorithms for real-time monitoring, fault detection, and predictive maintenance, reducing unexpected breakdowns.

High-Precision Blades: Made from specialized alloys, these blades deliver longer service life and superior cut quality.

Automated Material Handling: Incorporates robotic sheet loaders and unloaders that minimize manual handling errors and increase safety.

Energy-Efficient Design: Optimized for low power consumption, aligning with sustainable manufacturing practices.

These features ensure that Hengli's silicon steel shearing lines not only meet but exceed industry standards, providing manufacturers with a competitive edge.

Durability and Reliability for Long-Term Investment

Investing in high-quality shearing equipment is critical for long-term operational success. Hengli's shearing lines are constructed with robust materials and precision-engineered components designed to withstand harsh industrial environments.

Our frame structures are reinforced for vibration resistance, while wear-resistant blades and advanced lubrication systems extend service life. The reliable hydraulic and electrical systems are engineered for consistent performance over decades, ensuring minimal downtime and maximized ROI.

Customization and Scalability for Diverse Manufacturing Needs

Every manufacturer has unique requirements based on production volume, product specifications, and technological integration. Hengli offers customizable shearing solutions tailored to meet specific industry demands.

Whether handling small batch runs or mass production, our modular shearing lines can be scaled and configured for multi-layer cutting, variable sheet sizes, and specialized lamination geometries. Our engineering team works closely with clients to develop bespoke solutions that align with their growth strategies.

Commitment to Sustainability and Eco-Friendly Manufacturing

In an era where environmental responsibility is paramount, Hengli's silicon steel shearing lines incorporate energy-saving technologies and eco-conscious materials. Our equipment reduces waste generation through precise cutting and optimized material utilization.

Moreover, the low noise operation and reduced power consumption contribute to safer, greener factories. Hengli is dedicated to supporting sustainable manufacturing practices that meet regulatory standards and corporate social responsibility goals.

Global Service Network and Technical Support

Hengli is a professional silicon steel shearing equipment manufacturer, committed to technological innovation and product development, continuously improving the performance and efficiency of silicon steel shearing production lines, and providing better solutions for the power industry. We have an experienced technical team, providing professional technical support and customized services. Choosing Hengli means choosing an efficient, reliable and professional partner to jointly promote the sustainable development of the power industry. Our main products include: unwinding and leveling shearing production line; rotary shearing production line; silicon steel shearing equipment; coil cutting production line; and other precision tools and testing instruments. Welcome to contact us for more information and discuss your specific needs with our experts.

Choosing Hengli means gaining access to a comprehensive support system. Our global service network offers installation assistance, routine maintenance, training programs, and rapid spare parts supply.

Our dedicated technical team ensures that clients experience seamless integration, minimal downtime, and continuous operational excellence. We prioritize customer satisfaction by providing tailored solutions and ongoing innovation.

Conclusion: Why Hengli's Silicon Steel Shearing Lines Are the Industry Standard

Leading manufacturers worldwide recognize that precision, efficiency, durability, and customization are essential for competitive advantage in silicon steel processing. Hengli's advanced shearing lines deliver unparalleled performance and reliability, making them the preferred choice for high-volume, high-precision manufacturing.

Our relentless focus on technological innovation, sustainable practices, and customer-centric solutions positions Hengli as the industry leader in silicon steel shearing technology. Partnering with Hengli means investing in cutting-edge equipment that drives growth, reduces costs, and ensures product excellence for years to come.

Hengli is a professional silicon steel shearing equipment manufacturer, committed to technological innovation and product development, continuously improving the performance and efficiency of silicon steel shearing production lines, and providing better solutions for the power industry. We have an experienced technical team, providing professional technical support and customized services. Choosing Hengli means choosing an efficient, reliable and professional partner to jointly promote the sustainable development of the power industry. Our main products include: unwinding and leveling shearing production line; rotary shearing production line; silicon steel shearing equipment; coil cutting production line; and other precision tools and testing instruments. Welcome to contact us for more information and discuss your specific needs with our experts.

Choose Hengli — your trusted partner for advanced silicon steel shearing lines, and experience the future of steel manufacturing today.